Schilke Bells

The company offers eight different sizes of bells. Originally the

bells were given letters (e.g., "A," "B," "C," with "A" being the

largest). In about 1982 the bells were redesignated with numbers,

starting with "1" as the largest, but many people (including me in

this site) continue to refer to them with the original letters. The

"H" bell is the smallest and it is found on the piccolo trumpets. The

S series horns, the S42, S32, S22, and S22C all share the same

heavier bell, which Schilke identifies as the #2J, the "J" presumably

standing for Jeninga, for reasons set forth below. Most of the bells

are not Schilke designs but were copies of bells designed and used by

other companies which had playing characteristics that Mr Schilke

admired. For instance, the "C" bell used on the B2, B3, C2, C3, C5,

CX5, and occasionally the E3L-4, is a Besson design, and the "E" bell

used on the company's G1L-4 is a Buescher design. The descriptions of

each horn on this site makes reference to the bells, by letter, that

are standard with each model.

Lawrence Van Ameyde told me that he has learned about another bell that Schilke at one time developed: the "O" bell, which was larger than the "A", and was made for Adolph Herseth, the famed principal trumpet player of the Chicago Symphony during the time that Herseth basically lived at the Schilke factory. It was huge bell that only Herseth could control. Just a handful were ever made and unfortunately the mandrel was dropped and broken. It was never replaced, for economic reasons, and the "O" bell was never officially put into production. Lasse Rømer, a trumpet player in Denmark, reported to me that he owns an X3L with the O bell that was made in 1980.

Schilke, however, describes the bells relatively, rather than absolutely as Large, Medium Large, and Medium in the listed specifications for each instrument. For example, the B1 is a ML bore horn, with a L bell; the B2 a ML bore with a M bell. In this case the L bell on the B1 is Schilke's A bell; the M bell on the B3 is Schilke's C bell. On the B flat and C trumpets and cornets, the models in the current catalog and price list have either an A, B. or C bell. It gets a little complicated for the smaller trumpets. For example, the bell on the E3L is described as having a M bell, but this is Schilke's D size bell, not the same M bell as found on the B flat and C trumpets, which is Schilke's C bell. If one wanted the L bell on an E flat trumpet (a somewhat popular choice for the E3L-4), one would get the Schilke B bell, the ML bell on the B flat.

Schilke could have chosen better terms to describe the size and shape of each bell, which can be misleading. They differ in shape, not so much size. Generally these bell size labels apply to the shape of the bell, with the "larger" bells having flares that are more gradual and conical, i.e., that open earlier so that there is a wider cross section at a spot 3 inches, say, from the bell bead for the L bells than the M bells, very roughly along the lines of a flugelhorn. This tends to give the larger belled horns such as the B1, B7, and X3 a slightly darker sound. In addition, the larger bell horns do tend to have slightly larger diameters at the end of the flare, at least the L diameter is just a tiny bit bigger than the ML (I've compared a B1 and B5) and I'd bet the same is true for the ML and M bells. The more significant difference, however, is in the shape of the flare rather than in the ultimate diameter.

Brass Bells. From the company's inception until 1982, Schilke made and acquired the brass bells from various sources, made using a number of different materials, and using a number of different processes. Since that time, Schilke has made none of the bells in-house and rely on two different sources for bells. The brass bells are currently made by the Jeninga Brothers in Delavan, Wisconsin, using a secret process developed by former Schilke employee Paul Jeninga. The Jeninga Brothers bells are seamless and made out of shell casing brass. I have read that the process starts with a cylinder of brass that has a small hole drilled through the center and then, with a unique piece of equipment, the cylinder is stretched over a bell mandrel.

Lightweight copper bells. As an option on most of

their horns, Schilke makes available what they labeled as a

"beryllium bronze" bell which were originally made by Kiefer in

Elkhart, Indiana, and are now made by Anderson Plating. While these

may have had trace elements of beryllium at one time, but because of

the toxicity of beryllium, for more than 15 years, according to a

former employee, the bells have been made of pure copper, fabricated

electrolytically, i.e., the same way that silver plating is applied.

This means that these bells are made without seams. They are

indicated with a small "B" stamped into the ferrule on the bell tail

closest to the first valve casing. The beryllium bell has been the

standard bell on the Schilke P5-4 since the early 80s. The name

'beryllium bronze" has continued in use, even though it is

inaccurate, because the company did not wish to endure the confusion

created by a change in terminology.

Lightweight copper bells. As an option on most of

their horns, Schilke makes available what they labeled as a

"beryllium bronze" bell which were originally made by Kiefer in

Elkhart, Indiana, and are now made by Anderson Plating. While these

may have had trace elements of beryllium at one time, but because of

the toxicity of beryllium, for more than 15 years, according to a

former employee, the bells have been made of pure copper, fabricated

electrolytically, i.e., the same way that silver plating is applied.

This means that these bells are made without seams. They are

indicated with a small "B" stamped into the ferrule on the bell tail

closest to the first valve casing. The beryllium bell has been the

standard bell on the Schilke P5-4 since the early 80s. The name

'beryllium bronze" has continued in use, even though it is

inaccurate, because the company did not wish to endure the confusion

created by a change in terminology.

These bells are very light weight, almost unbelievably so, and as the Schilke brochure states, "project very well with more of the 'higher overtones' present....at all dynamic levels." Research into the projection of comparable brass and beryllium bells by Schilke found that over a given distance a drop in sound level of 5% was recorded for the beryllium bells, compared to 12% for a brass bell.

In addition they improve the already quick response of Schilke trumpets. These bells may not be for everyone, but playing a tuning bell Schilke with the beryllium bell is something that everyone should try if presented with the opportunity. It is also instructive to remove the bell and hold it in your hand. Its lack of heft is astonishing.

For the past several years, they have weighed anywhere from 7-9 ounces (9 being the heaviest made). The ones made back in the 60s and 70s weigh less, around 6-7 ounces. Bill Chase had a 6 1/2 ounce bell and one was made for Jon Faddis that was even lighter, around 4-5 ounces.

According to a former employee, the beryllium bronze bells are very difficult to work with and it would not be unusual to destroy two of the bells while trying to fit one to a horn.

Additionally, Peter Bond, of the New York Metropolitan Opera Orchestra reports that the beryllium bells have something of a "memory"; a dent, once repaired, will often partially return. Others have confirmed that phenomenon.

When ordering a Schilke trumpet, the beryllium bell currently adds $100 to the list price of the horn. Some retailers may offer the option at a small discount.

Standard weight copper bells. Although it is entirely unadvertised, the bells on the B5 and B6 trumpet models and "some cornet models" are made from a heavier weight of copper. I was surprised when I heard this and immediately checked my daughter's 1976 B5 where there is a small oval under the bell near valve casing where the silver plate has worn away. Yep, it is copper.

Tuning bells

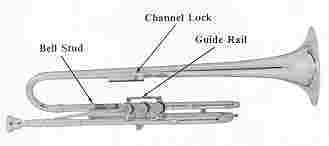

The

Schilke catalog states: "Detachable tuning-bells are available on all

Schilke custom built trumpets. The advantage of the tuning bell

feature is that the tuning slide can be left all the way in or moved

only a little, thereby keeping the bore relatively free of gaps that

may cause a disturbance in the nodal pattern of the sound wave.

Another advantage is that different bells of varying sizes and

materials can be used to change some of the characteristics of the

instrument. The main drawback to the tuning-bell instrument is that

it is more fragile because of the lack of the second brace.

Consequently extra care must be taken to prevent damage to the

instrument." For a full discussion of the research conducted by

Schilke behind the tuning-bell trumpet design, see Colin Bloch's

article, The Bell-Tuned

Trumpet.

The

Schilke catalog states: "Detachable tuning-bells are available on all

Schilke custom built trumpets. The advantage of the tuning bell

feature is that the tuning slide can be left all the way in or moved

only a little, thereby keeping the bore relatively free of gaps that

may cause a disturbance in the nodal pattern of the sound wave.

Another advantage is that different bells of varying sizes and

materials can be used to change some of the characteristics of the

instrument. The main drawback to the tuning-bell instrument is that

it is more fragile because of the lack of the second brace.

Consequently extra care must be taken to prevent damage to the

instrument." For a full discussion of the research conducted by

Schilke behind the tuning-bell trumpet design, see Colin Bloch's

article, The Bell-Tuned

Trumpet.

The

other, and more dramatic, effect of the tuning bell option, in my

opinion, is the removal of the far bell brace which results in the

increased responsiveness of the bell and changed projection

characteristics. The bell becomes free to vibrate without

stabilization from the second valve to the end of the bell. Contrast

that to the conventional brace on a horn with a conventional turning

slide, like a Bach, where the brace is a matter of a few inches from

the end of the bell flair. Such things do make noticeable

differences. From a Schilke lightweight, especially with the larger

bells, the sound seems to radiate out in a larger arc than, say, a

heavier weight horn with braces near the bell flair where the sound

seems to emanate from the horn in a narrower arc, focused directly in

front of the player--at least that seems to be the sensation to me.

The effect is even more pronounced in the extremely heavy horns such

as those now made by Monette, Taylor, Courtois.

The

other, and more dramatic, effect of the tuning bell option, in my

opinion, is the removal of the far bell brace which results in the

increased responsiveness of the bell and changed projection

characteristics. The bell becomes free to vibrate without

stabilization from the second valve to the end of the bell. Contrast

that to the conventional brace on a horn with a conventional turning

slide, like a Bach, where the brace is a matter of a few inches from

the end of the bell flair. Such things do make noticeable

differences. From a Schilke lightweight, especially with the larger

bells, the sound seems to radiate out in a larger arc than, say, a

heavier weight horn with braces near the bell flair where the sound

seems to emanate from the horn in a narrower arc, focused directly in

front of the player--at least that seems to be the sensation to me.

The effect is even more pronounced in the extremely heavy horns such

as those now made by Monette, Taylor, Courtois.

The tuning bell models were introduced in the late 60's, though there were some custom models made earlier. Those horns with tuning bells are designated by adding an L to the model number, e.g., a Schilke B5 with a tuning bell is a Schilke B5L. The tuning bell design is the sole patent developed and registered by Renold Schilke, which is one more than that held by Vincent Bach, Elden Benge, or Dominic Calicchio. The patent however was transferred to Yamaha by Schilke shortly after its registration because Schilke believed that only a company with Yamaha's resources would be financially able to defend the patent against infringement. Schilke was proven right and by the end of the 70's Yamaha had sued F. E. Olds & Son over their use of the tuning bell design.

I would estimate that the tuning bell horns make up about a quarter (give or take ten percent!) of the sales of the lightweight B flat and C trumpets. S series horns are also available with a tuning bell, though they are sold in very small numbers. Currently the tuning bell option adds $285 to the list price of the horn. Some retailers may offer the option at somewhat less.

In the smaller trumpets, the tuning bell made the conversion from one key to another much more practical and satisfying since the bell could be easily changed as well as the slides. Thus, the introduction of the E3L and G1L have made the Schilke fixed bell smaller trumpets almost obsolete.

Additional bells in brass or beryllium are available for tuning bell trumpets. Thus one may wish a large beryllium bell for maximum projection in a big band setting, but prefer a smaller brass bell for chamber ensemble. Additional bells in silver are currently priced for brass at $290 and for beryllium at $390. These are list prices and some retailers may sell them below list price.

Additional slides

Slides which change a C trumpet to B flat ($250); D trumpet to C

($250), and E flat to D ($280) are available at extra cost. These

slides are silver plated but available in gold plate at extra cost.

The E flat/D combination is quite popular, but the other two

conversions are not very common since the performance, particularly

intonation, of the lower pitched horn suffers.

Trumpet finish

Schilke horns are available in only silver and gold plating. To

order gold plating one must contact the factory and receive a price

quotation based on the most recent price of gold. Schilke horns are

not available in raw brass or in lacquer as a result of a famous

study done by Mr. Schilke surveying

the properties of raw, plated,

and lacquered horn. The study is contained in the

Schilke Brass Clinic.

According to Ed Kennedy, a former employee, the company did make lacquered horns on occasion, usually to fill a U.S. military order. The horns were prepped exactly the same but sent to Lyons Band Instrument Company to be lacquered rather than Anderson Plating. However Mr. Schilke remained adamant about the superiority of silver plating.

That position was made clear to Ken Taylor, a student of Clifford Lyllia at the University of Michigan, a good friend of Mr. Schilke, who said that he took a wounded Benge to Schilke to have a Schilke lead pipe installed, and Schilke would not return the finished horn to Mr. Taylor until he stripped the lacquer and plated it.

For a look at a brushed gold plated finish, take a look at this.

© 1999 - 2006 by James F.

Donaldson

All rights reserved